Down The Hole Hammers

1. Down the hole hammers have high drilling accuracy and stability, and can perform drilling operations under various geological conditions. Whether it is hard rock or soft soil, down-the-hole hammer can effectively complete the drilling task.

2. The structure of down the hole hammers is simple, easy to operate and maintain.

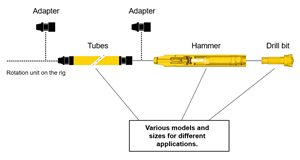

3. Down the hole hammers are suitable for different drilling diameter and depth requirements. Drill bits and drill pipes of different specifications can be selected according to specific operation requirements to meet different drilling requirements.

- Information

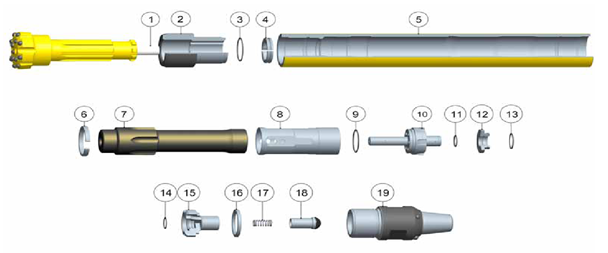

Introduction to down the hole hammer:

A down the hole hammer is a tool used to punch holes. It consists of a hollow steel head with one or more bits on it and a hollow shank for drilling operations underground or underwater. DTH hammers are usually used in construction, mining, rock exploration and other fields, and can drill into deeper formations. The principle of down the hole hammer is to make the drill bit rotate and impact in the formation by hammering the steel head to achieve the purpose of drilling.

Advantages of down the hole hammer:

1. Down the hole hammer provides users with higher perforation efficiency. It saves costs for users and improves economy.

2. The drill watch has high reliability and long service life.

3. The dth hammers are made of high quality steel. The factory has advanced and first-class production equipment and perfect technology, which ensures the high reliability of the product, thus ensuring the ideal drilling life of the product and saving costs for users.

4. The internal component structure of dth hammers is more convenient to maintain and win effective working time for users. More economical repair kits save maintenance and repair costs for users.

Parameters of down the hole hammer:

| dth hammer 9 models more than 70 kinds of products | ||||||||

| 2” | 3,5” | 4” | 5” | 6” | 8” | 9/10" | 12” | 20” |

DTH Hammer Adaptation:

1. Aperture 100-254mm.

2. Hole depth > 15m.

3. The demand for straight holes requires good hole quality 4. High requirements in broken and broken ground.

4. Drilling conditions with demanding availability and utilization.

Company Profile:

We are dedicated to rock drilling rigs and rigs, rock excavation and construction equipment and auxiliary materials for surface and underground operations, and can provide high-quality products and after-sales services. We can provide you with various types of OEM spare parts, with the purpose of improving production Ability to reduce usage costs.

Based on the advantages of rock drills, we can provide customers with upgrading and transformation services, and provide perfect solutions for customers' production needs.