Rock Drilling Rig BOOM

1. Rock drill booms adopt advanced rock drilling technology and mechanical structure design, which can perform rock drilling operations quickly and efficiently.

2. Rock drill booms adopt high-strength structural materials and advanced safety protection devices, which can ensure the safety and reliability of the operation process.

3. Rock drill booms adopts humanized design and operation interface, which is convenient for operators to get started and operate quickly.

- Information

Introduction of Rock drill booms:

Rock drill booms are heavy duty structures used to support and position rock drills in mining and construction operations. These booms are usually made of strong and durable materials, such as steel, and are designed to withstand the high forces and vibrations that occur during rock drilling.

Features of Rock drill booms:

Rock drill booms are mounted on excavators or other heavy machinery and can be adjusted to reach different drilling positions. They provide stability and precision to the drilling process, allowing operators to precisely target specific areas for drilling.

Rock drill booms often have multiple joints and hydraulic systems that allow them to rotate, extend and articulate in different directions. This flexibility allows the operator to access hard-to-reach areas and adapt to the shape and contours of the rock face.

Rock drill booms are equipped with a variety of attachments including rock drills, hydraulic breakers and other drilling tools. Powered by hydraulic or pneumatic systems, these attachments are capable of breaking and digging rock and other hard materials.

Rock drill booms play a vital role in rock drilling operations, providing stability, precision and versatility to ensure an efficient and effective drilling process in the mining and construction industries.

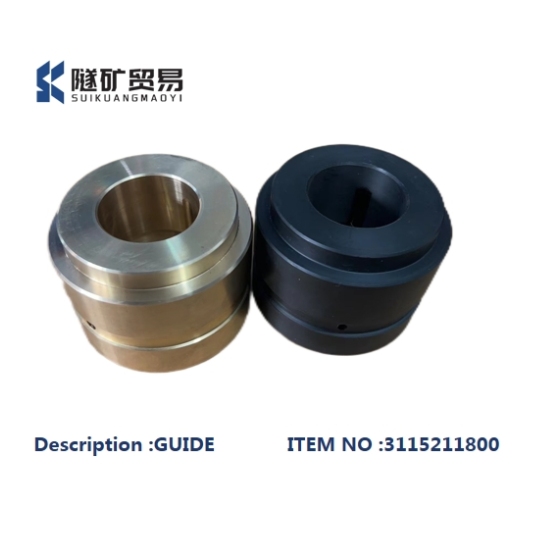

| Part Number | Name | Part Number | Name |

| 3128 3146 72 | CYLINDER LINK | 3125 1974 80 | EXPANDING SHAFT |

| 3128 3154 51 | SHAFT COMPL. | 3128 3069 51 | SHAFT |

| 3125 4946 80 | EXPANDING SHAFT | 3125 1982 80 | EXPANDING SHAFT |

| 3125 1981 80 | EXPANDING SHAFT | 3125 4937 80 | EXPANDING SHAFT |

| 3128 3083 03 | SHAFT | 9121 7017 02 | HYDR. CYLINDER |

| 3125 1981 81 | EXPANDING SHAFT | 3128 0251 10 | CYLINDER GUARD |

| 9121 7032 00 | HYDR. CYLINDE | 3128 0251 02 | ATTACHMENT |

| 3128 3035 70 | PROTECTION | 3128 2800 08 | THRUST BEARING |

| 3128 3035 71 | PROTECTION | 3128 2800 09 | THRUST BEARING |

| 3128 3035 69 | SUPPORT | 3128 2800 10 | THRUST BEARING |

| 3128 0902 00 | SPACER | 0663 2135 00 | O-RING |

| 3125 4968 80 | EXPANDING SHAFT | 0500 4520 03 | BUSHING |

| 3128 2800 09 | THRUST BEARING | 3177 0074 00 | BEARING BUSHING |

| 3128 2800 08 | THRUST BEARING | 3128 3038 97 | BUSHING |

| 3128 3069 55 | BOLT | 9128 7344 00 | BUSHING |

| 0663 6136 00 | O-RING | 0501 0000 16 | BEARING,SP.PL. |

| 3128 3038 97 | BUSHING | 3128 2592 43 | HYDR. CYLINDER |

| 3177 0074 01 | BEARING BUSHING | 3122 0309 00 | RUBBER RING |

| 3128 3038 97 | BUSHING | 3128 3219 00 | HYDR. CYLINDER |

| 9106 0630 10 | DOUBLE CH.VALVE | 3125 4968 80 | EXPANDING SHAFT |

| 9106 0630 11 | DOUBLE CH.VALVE | 3125 4952 80 | EXPANDING SHAFT |

| 9128 7345 00 | BUSHING | 3125 4924 00 | SHIM |

| 0501 0019 00 | BEARING,SP.PL | 0666 8096 03 | AXIAL SEAL |

| 3125 4976 01 | CRADLE | 5724 0011 95 | HOSE HOLDER |

| 3128 3125 77 | KEY | 3128 3126 44 | TURNING DEVICE |

| 3128 3020 00 | PIN | 3128 3140 86 | PROTECTION |

| 3125 4944 03 | BEARING HOUSING | 0500 4500 03 | FLANGE BEARING |

| 3128 2165 00 | COVER | 3128 3141 67 | BUSHING |

| 3128 2166 00 | SEAL | 3128 3219 86 | PLAIN BEARING |

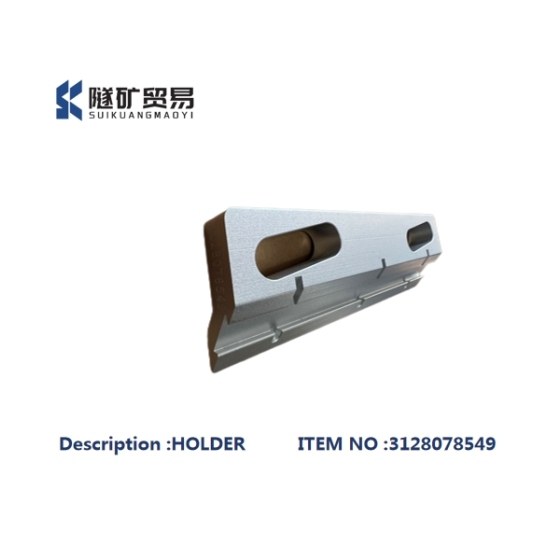

| 3128 2169 00 | BUSHING SEGMENT | 3128 3061 81 | HOLDER |

| 3128 3219 59 | WASHER | 3128 3061 80 | HOLDER |

| 0101 1364 00 | PIN | 3128 0940 00 | ATTACHM. PLATE |

| 0102 0415 00 | PIN | 3128 3074 88 | SLIDING PIECE |

| 0544 2162 00 | GREASE NIPPLE | 3128 0784 39 | HOLDER |

| 0211 1962 81 | SCREW | 3128 0784 38 | HOLDER |

| 0211 1963 47 | SCREW | 5112 3036 39 | WAIST PIN |

| 0211 1327 03 | SCREW | 5112 3036 38 | PLAIN BEARING |

| 0686 9252 27 | PROTECTION CAP | 8231 0854 19 | BREATHER FILTER |

| 3128 2800 07 | LINK |

The maintenance method of Rock drill booms is as follows:

1. Regular cleaning: Use a clean rag or brush to clean the dust and dirt on the surface of the motor arm to ensure that the motor arm remains clean.

2. Lubrication: Lubricate the key parts of the drill boom according to the requirements of the operation manual of the mobile arm. Lubricate with suitable oil or grease to reduce friction and wear.

3. Check Fasteners: Regularly check the fasteners on the maneuvering arm to make sure they are tight. If any loose bolts or nuts are found, retighten them immediately.

About us:

We are dedicated to rock drilling rigs and rigs, rock excavation and construction equipment and auxiliary materials for surface and underground operations, and can provide high-quality products and after-sales services. We can provide you with various types of OEM spare parts, with the purpose of improving production Ability to reduce usage costs.

Based on the advantages of rock drills, we can provide customers with upgrading and transformation services, and provide perfect solutions for customers' production needs.