- Home

- >

- Products

- >

- Top Hammer Rods

- >

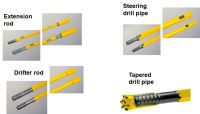

Top Hammer Rods

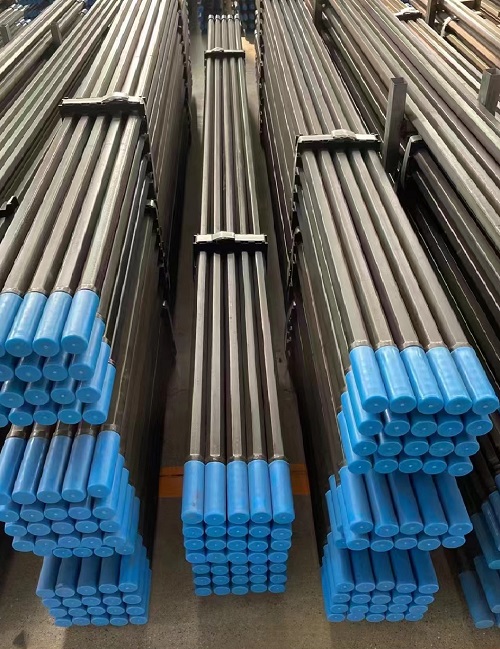

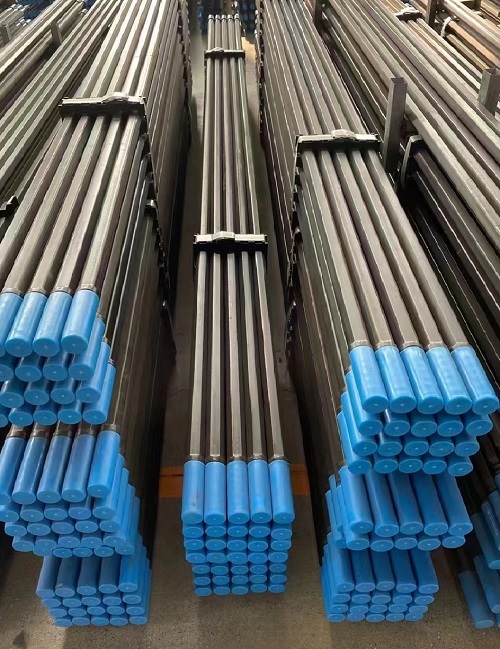

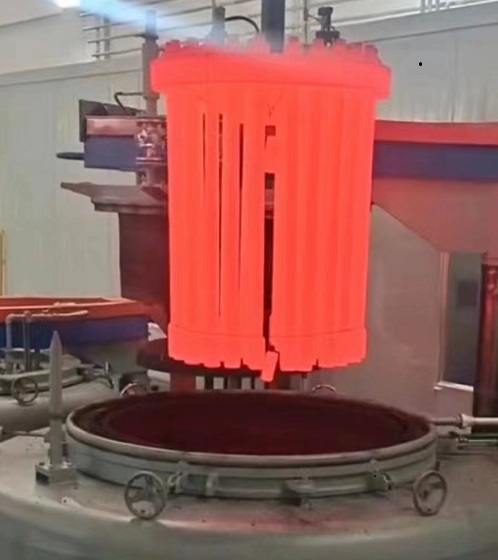

1. The material used in rock drill rod is Shanghai Baosteel 23CrNi3Mo, which is treated by integral vacuum air conditioning.

2. Advanced imported CNC lathe is used in thread processing, which greatly improves the fatigue resistance and impact force of drill rods.

3. Drill bit extension rod it can be used with Atlas Copco, Epiroc, TamRock, Sandvik and other well-known rock drilling rigs.

- Information

Introduction of Top hammer rods:

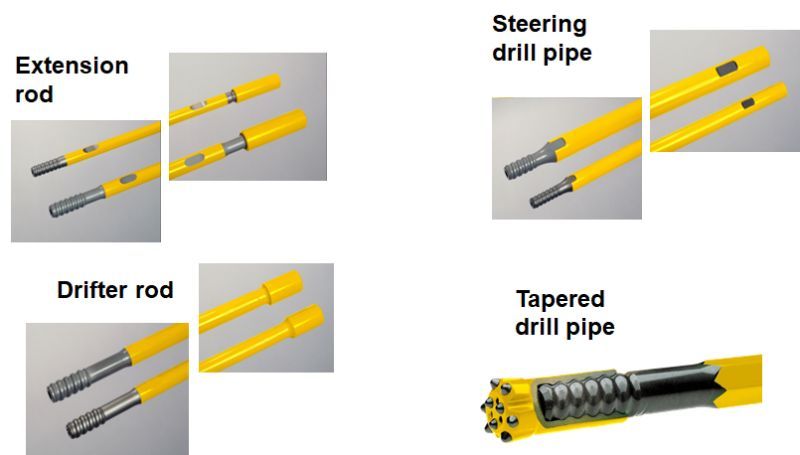

Top hammer rods are a type of drill rod used in underground drilling and engineering construction. Unlike conventional rotary drill pipes, tophammer drill pipes use impact force to drill rather than rotational force. Rock drill rod consists of drill bit, drill body, striker and joint. The impactor is driven by a pneumatic or hydraulic system to generate high-frequency impact force, which transmits kinetic energy to the drill bit, causing it to cut and break underground rock or soil. The rock drill rod has the advantages of high efficiency, strong adaptability, simple operation and high reliability, and is suitable for various geological conditions and rock types.

Top hammer rods have the following advantages:

(1) The welding quality of Top hammer rods is stable, the dimensional accuracy of the weldment is high, and the welding rejection rate is lower than that of resistance butt welding and flash butt welding.

(2) The welding productivity of Top hammer rods is high, 5-6 times higher than that of flash butt welding.

(3) Top hammer rods are mainly welding of dissimilar metals, such as the connection between carbon steel, low alloy steel and stainless steel, high-speed steel, the connection between copper and stainless steel, copper and aluminum, aluminum and steel, etc. .

(4) Top hammer rods have low processing cost, save electricity, and weldments do not need special cleaning.

(5) Drill bit extension rod is easy to realize mechanization and automation, simple operation, no sparks, arc light and microbial gas on the welding table.

Specification parameters of Top hammer rods:

| Serial number | Specification | Application range | Remark |

| 1 | R32 (1 1/4″) | Equipment for pneumatic rock drill | customizable |

| 2 | R32 (1 1/4″) | Equipment for long-hole drilling | customizable |

| 3 | T35 (1 3/8″) | customizable | |

| 4 | R38 (1 1/2″) | customizable | |

| 5 | T38 (1 1/2″) | customizable | |

| 6 | T45 (1 3/4″) | customizable | |

| 7 | T51 ( 2″ ) | customizable | |

| 8 | ST58 (2 1/4″) | customizable | |

| 9 | ST68 (2 3/4″) | customizable | |

| 10 | R28(1 1/8″) | Equipment for drifting and tunneling | customizable |

| 11 | R32(1 1/4″) | customizable | |

| 12 | R35(1 3/8″) | customizable | |

| 13 | R32(1 1/4″) | Equipment for surface drill rigs | customizable |

| 14 | R38(1 1/2″) | customizable | |

| 15 | T38(1 1/2″) | customizable | |

| 16 | T45(1 3/4″) | customizable | |

| 17 | T51( 2″ ) | customizable | |

| 18 | T60(2 3/8″) | customizable |

How to use Top hammer rods:

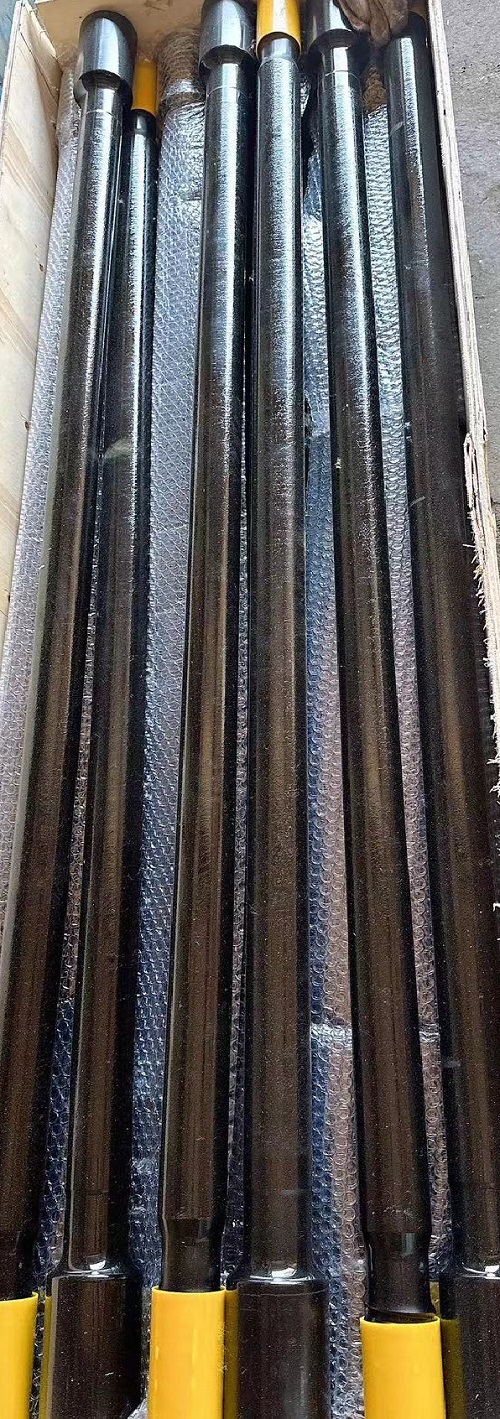

Our tophammer rods have threaded ends for a secure connection to the drill's hammer. The hammer's impact is then used to drive the rod into the ground, delivering a powerful blow to the bit. Energy transfer from the hammer to the drill rod ensures efficient and precise drilling. With good strength and design, these drill rods can effectively transfer energy from the impactor to the drill bit, thus improving drilling performance and speed.

Our services:

We provide top hammer rods for a variety of applications, including underground mining and tunnel excavation, opencast mining and quarrying, building drilling and blasting, and construction drilling and blasting. For example: bit extension rod, drift rod and so on.